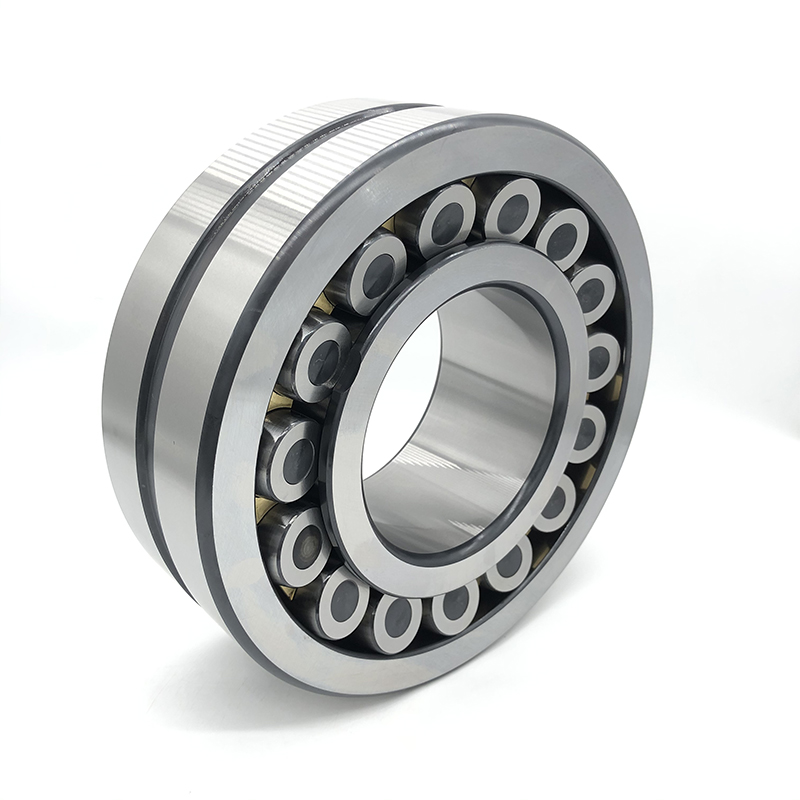

Manufacturing Companies for Napa Auto Parts Bearings - High-Precision Hub Bearing Car Bearing Rear Wheel Bearing JXC25469C – Yanlong

Manufacturing Companies for Napa Auto Parts Bearings - High-Precision Hub Bearing Car Bearing Rear Wheel Bearing JXC25469C – Yanlong Detail:

|

Bearing Detail |

|

| Item No. | JXC25469C |

| Bearing Type | High-Precision Hub Bearing |

| Ball Bearing seals | DDU, ZZ, 2RS |

| Number of Row | DOUBLE ROW |

| Material | Chrome steel GCr15 |

| Precision | P0,P2,P5,P6,P4 |

| Clearance | C0,C2,C3,C4,C5 |

| Noise | V1,V2,V3 |

| Cage | Steel cage |

| Ball Bearings Feature | Long-life with high quality |

| Low-noise with strict controlling the quality of bearing | |

| High-load by the advanced high-technical design | |

| Competitive price, which has the most valuable | |

| OEM service offered, to meet the customers requirements | |

| Application | Gearbox,auto,reduction box,engine machinery,mining machinery,etc |

| Bearing Package | Pallet,wooden case,commercial packaging or as customers requirement |

| Lead Time : | ||||

| Quantity(Pieces) | 1 – 5000 | >5000 | ||

| Est. Time(days) | 7 | To be negotiated | ||

Packaging & Delivery:

Packaging Details: Industrial; Single box + Carton + Wooden Pallet

| Package Type: | A. Plastic tubes Pack + Carton + Wooden Pallet |

| B. Roll Pack + Carton + Wooden Pallet | |

| C. Individual Box +Plastic bag+ Carton + Wooden Pallet | |

| The nearly port | Tianjin or Qingdao |

The traditional automobile wheel bearings are composed of two sets of tapered roller bearings or ball bearings. The mounting, oiling, sealing and clearance adjustment of the bearings are all carried out on the automobile production line.This kind of structure makes it difficult to assemble in the automobile production plant, high cost, poor reliability, and when the automobile is maintained in the maintenance point, it also needs to clean, grease and adjust the bearing.Wheel hub bearing unit is in the standard angular contact ball bearings and tapered roller bearings, on the basis of it will be two sets of bearing as a whole, has the assembly clearance adjustment performance is good, can be omitted, light weight, compact structure, large load capacity, for the sealed bearing prior to loading, ellipsis external wheel grease seal and from maintenance etc, and has been widely used in cars, in a truck also has a tendency to gradually expand the application.

The largest number of wheel bearings for cars used in the past was the use of single row tapered roller or ball bearings in pairs. With the development of technology, car hub units have been widely used in cars. The range and use of hub bearing units is growing, and today it has reached the third generation: the first generation consists of double row angular contact bearings. The second generation has a flange for fixing the bearing on the outer raceway, which can be simply fixed to the axle by a nut. Make the maintenance of the car easier. The third-generation hub bearing unit is equipped with a bearing unit and an anti-lock brake system ABS. The hub unit is designed with an inner flange and an outer flange, the inner flange is bolted to the drive shaft, and the outer flange mounts the entire bearing together.

The main function of the hub bearing is to load and provide precise guidance for the rotation of the hub. It is both an axial load and a radial load and is a very important component. The traditional automotive wheel bearings are composed of two sets of tapered roller bearings or ball bearings. The installation, oiling, sealing and clearance adjustment of the bearings are carried out on the automobile production line. This structure makes it difficult to assemble in a car production plant, high in cost, and poor in reliability, and the car needs to be cleaned, oiled, and adjusted at the time of maintenance at the maintenance point.

The hub bearing unit is developed on the basis of standard angular contact ball bearings and tapered roller bearings. It integrates two sets of bearings and has good assembly performance, can eliminate clearance adjustment, light weight, compact structure and load capacity. Large, sealed bearings can be pre-loaded with grease, omitting external hub seals and maintenance-free. They have been widely used in cars, and there is a tendency to gradually expand application.

Product detail pictures:

Related Product Guide:

Assume full responsibility to meet all demands of our clients; achieve continuous advancements by promoting the growth of our clients; become the final permanent cooperative partner of clients and maximize the interests of clients for Manufacturing Companies for Napa Auto Parts Bearings - High-Precision Hub Bearing Car Bearing Rear Wheel Bearing JXC25469C – Yanlong , The product will supply to all over the world, such as: Lithuania, Iran, Florida, We strive for excellence, constant improvement and innovation, is committed to make us the "customer trust" and the "first choice of engineering machinery accessories brand" suppliers. Choose us, sharing a win-win situation!

Staff is skilled, well-equipped, process is specification, products meet the requirements and delivery is guaranteed, a best partner!